Product Category

Winder, doubl...

- CY212 intelligent electronic yarn-guide winder

- CY215A intelligentelectronic yarn-guide winder

- CY215B Electronic yarn-guide Air coated

Large Package...

- CY250G Loose type two-for-one twister

- CY250B large package two-for-one twister

- CY250C large package two-for-one twister

Large Package...

Twisting seri...

- CY310 chemical fiber two-for-one twister

- CY250B large package two-for-one twister

- CY250C large package two-for-one twister

Staple Two-fo...

- CY208 staple fiber two-for-one twister

- CY128 staple fiber two-for-one twister

- CY256 staple fiber two-for-one twister

Fittings

Products >> Winder, doubler winder series

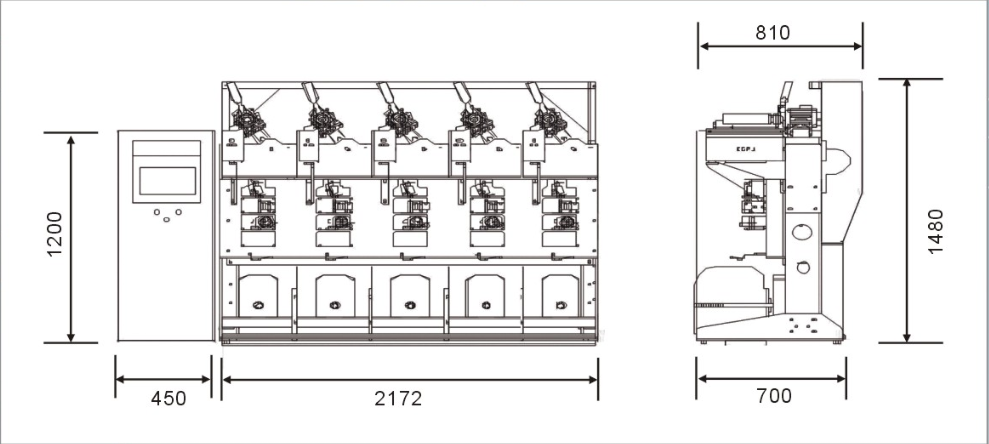

CY212 intelligent electronic yarn-guide winder

.jpg)

Winding machine with all aspects of performance reaching the international advanced level

CY212 intelligent Electronic yarn guide winder is mainly used for the equipment of one bobbin to be poured into another bobbin; it can be used for the twisting of various yarns and to meet the forming requirements.

1 Features:

◎The high-performance servo motor guide yarn can achieve a line speed of 800 m/min or even 1100 m/min, which can double the production efficiency and reduce the production cost.

◎Using comprehensive intelligent control technology, it can meet various parameters related to yarn quality, such as forming length, edge angle, edge width, soft edge density, forming cross angle and winding strength.

◎Adopt intelligent online tension system, active retraction yarn feeding system and automatic tracking super-feeding system to ensure high uniformity of package density.

◎The whole machine has beautiful appearance, low noise, low power consumption and high efficiency operation. The man-machine interface is optimized and the control is more reasonable.

A: Applied to active retreat:

It is suitable for active retracting and rewinding of skein or bobbin such as DTY, viscose rayon, staple fiber.

1 technical parameters:

|

Machine structure |

Single-sided single layer, multiple of 4 spindles, 60 spindles/set |

|

Spindle distance |

440mm |

|

Winding method |

Digital winding or precision winding |

|

Mechanical speed |

Up to 1100 m / min |

|

Strength mode |

Electronic online strength + active retreat |

|

Winding tube |

Parallel or tapered tube |

|

Winding stroke |

130mm~260mm (freely programmable) |

|

Forming method |

Straight or beveled molding (angle can be adjusted freely) |

|

Installed power |

400W/ingot |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

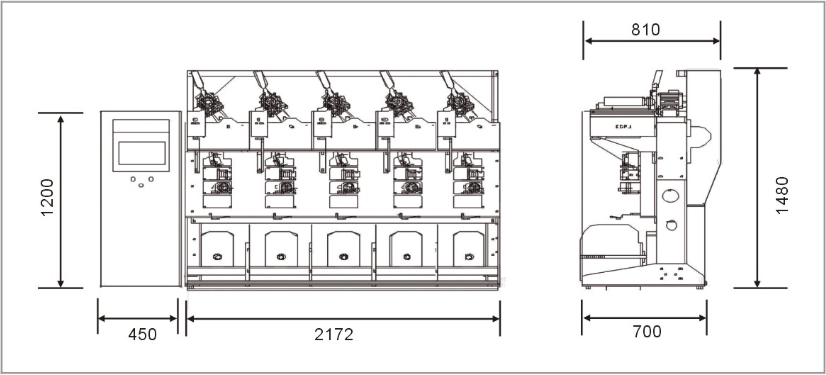

B: applied to the loose tube winding:

Suitable for DTY, FDY, POY, viscose rayon, staple fiber, industrial yarn, etc.

1 technical parameters:

|

Machine structure |

Single-sided single layer, multiple of 5 spindles, 60 spindles/set |

|

Spindle distance |

360mm |

|

Winding method |

Digital winding or precision winding |

|

Mechanical speed |

Up to 1100 m / min |

|

Strength mode |

Electronic online tension, electronic gate-gear force combination, heavy hammer gate tension (optional) |

|

Winding tube |

Parallel or tapered tube |

|

Winding stroke |

130mm~260mm (freely programmable) |

|

Forming method |

Straight or beveled molding (angle can be adjusted freely) |

|

Installed power |

400W/ingot |

|

Actual power consumption |

90W/ingot |

.jpg)

.jpg)

.jpg)

C: applied to the yarn

Applicable to 1~6 combined yarns such as DTY and staple fiber.

.jpg)

Mobile phone

Mobile phone Micro-channel

Micro-channel Home

Home