Product Category

Winder, doubl...

- CY212 intelligent electronic yarn-guide winder

- CY215A intelligentelectronic yarn-guide winder

- CY215B Electronic yarn-guide Air coated

Large Package...

- CY250G Loose type two-for-one twister

- CY250B large package two-for-one twister

- CY250C large package two-for-one twister

Large Package...

Twisting seri...

- CY310 chemical fiber two-for-one twister

- CY250B large package two-for-one twister

- CY250C large package two-for-one twister

Staple Two-fo...

- CY208 staple fiber two-for-one twister

- CY128 staple fiber two-for-one twister

- CY256 staple fiber two-for-one twister

Fittings

Products >> Large Package Two-for-one Twister (garment fabric series)

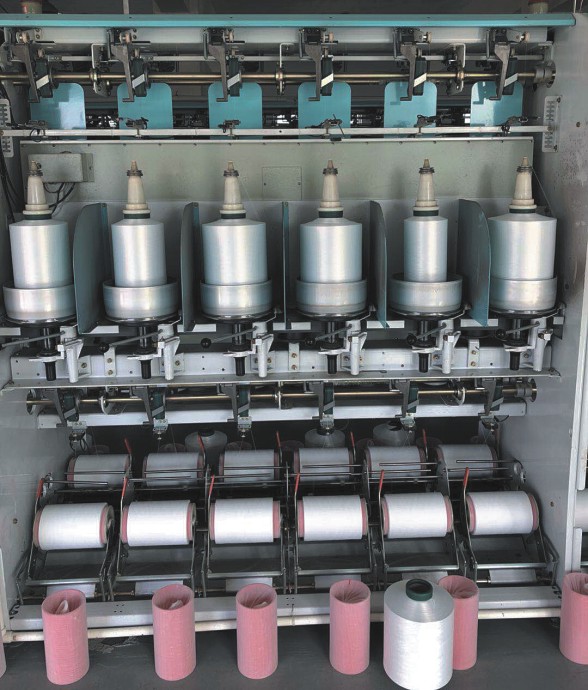

CY250G Loose type two-for-one twister

Scope of application: It is suitable for the twisting of 20D-500D high elastic and medium fiber of nylon, polyester and so on.

Process characteristics:

a, the delicate design of the super-feeding system minimizes the elastic loss of the elastic fiber during the twisting process;

b. Accurately calculated Loose type winding density not only ensures the least elastic loss during the dyeing process, but also saves the dyeing cost;

c. Direct Loose type bobbin winding reduces the processing process of elastic fiber (twisting, steaming, etc.) while reducing the loss of yarn;

d. Supporting constant-strength force to actively de-winding the winding machine, which perfectly guarantees that the yarn after dyeing is smoothly deconstructed and the winding strength is always the same, and the quality of the yarn is greatly improved;

e. Reduce equipment and site investment in the process, saving labor costs.

Features:

a, convenient operation, reasonable transmission, compact structure and beautiful appearance;

b, manual release spindle brake system, the operation is simpler, while extending the life of the belt and spindle;

c. Fully variable frequency control system and visual human-machine interface to facilitate adjustment and monitoring of process parameters.

Optional equipment:

a. Yarn breaking device: It can avoid yarn waste and mechanical loss caused by yarn interruption during yarn twisting process;

b. Compact winding device: This device is equipped with a device for super-feeding and over-feeding on the Loose type super-feeding edge, so that the device can conveniently carry out the traditional twisting of the same yarn at the same time.

Technical Parameters:

| Operational form | Double-sided single layer, threading thread (or pneumatic threading) |

| Number of spindles | 10 (or 12) spindle multiples, standard 100 spindles (or 120 spindles) |

| Spindle distance | 366mm (or 300mm) |

| Spindle speed range | 2000-7000r/min |

| Width range | 35-500T/M |

| Orientation | S or Z |

| Spindle tensioner | Steel ball |

| Winding stroke | 240mm-270mm or 190mm-210mm |

| rated power | 18.5KW |

| Startup mode | Frequency conversion slow start |

| Winding speed | Up to 120 m / min |

| Volume | Up to 5 kg |

Mobile phone

Mobile phone Micro-channel

Micro-channel Home

Home